The production of welding machines (especially modern inverter welding machines) is a precision manufacturing process that integrates electronics and mechanics. Its core lies in assembling hundreds of parts, including electronic components and metal structural parts, into a stable and reliable welding device through a series of processes.

Shenzhen Woweld Electric Co., Ltd., based on over twenty years of design and production experience in the industry and drawing inspiration from the production line layouts of renowned domestic companies, has perfected its main processes and key links from design to finished product:

Core Manufacturing Process of Welding Machines

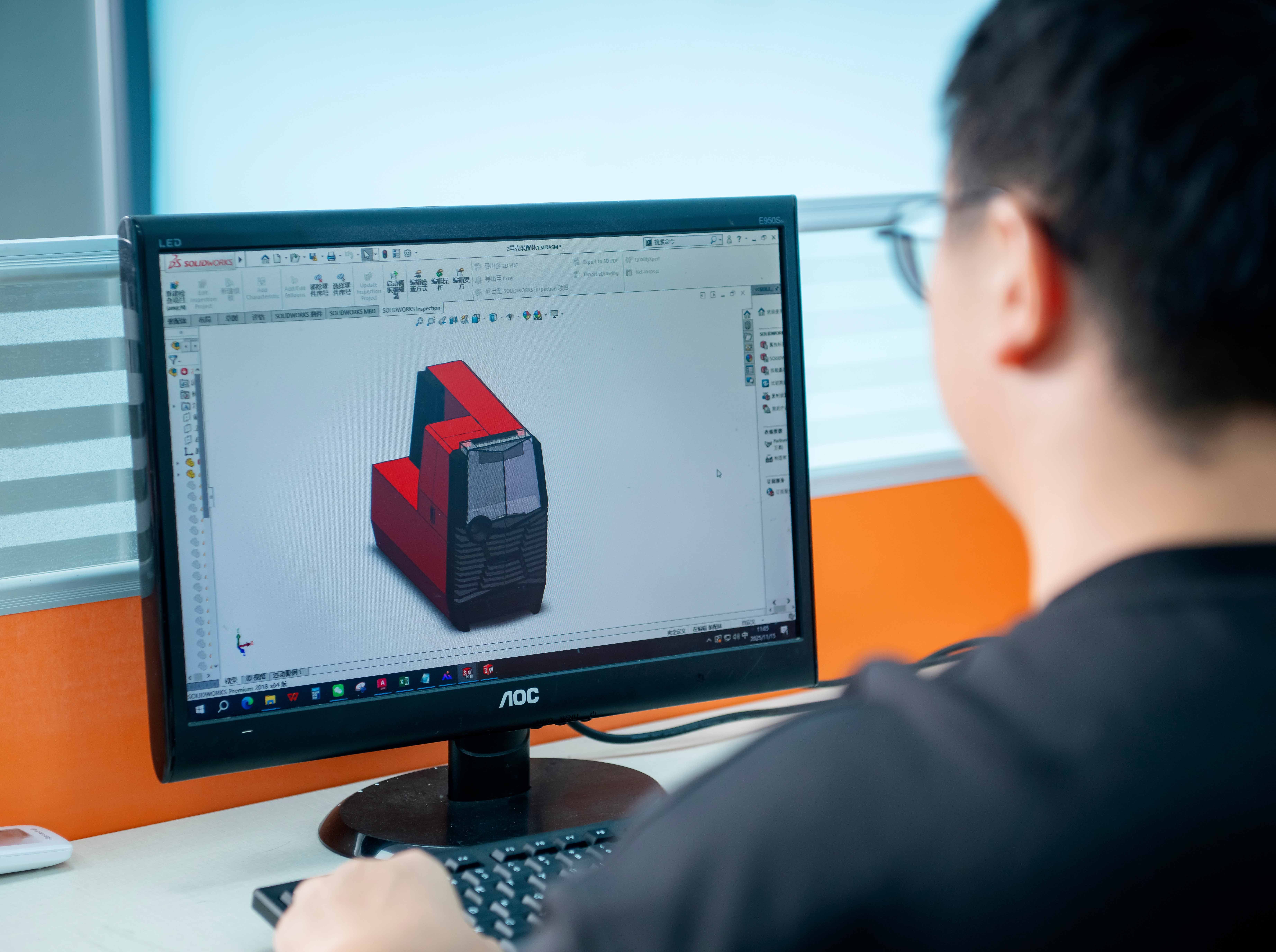

1. R&D

· Key Steps: Circuit Design, Structural Design, Software Programming

· Core Outputs: Technical Drawings, Software Programs, Bill of Materials

2. Electronic Component Manufacturing

· Key Steps: Material Preparation, PCB Surface Mount Technology (SMT), Manual Insertion and Re-soldering, PCBA Testing

· Core Outputs: Tested and qualified control boards, power boards, and other core circuit boards

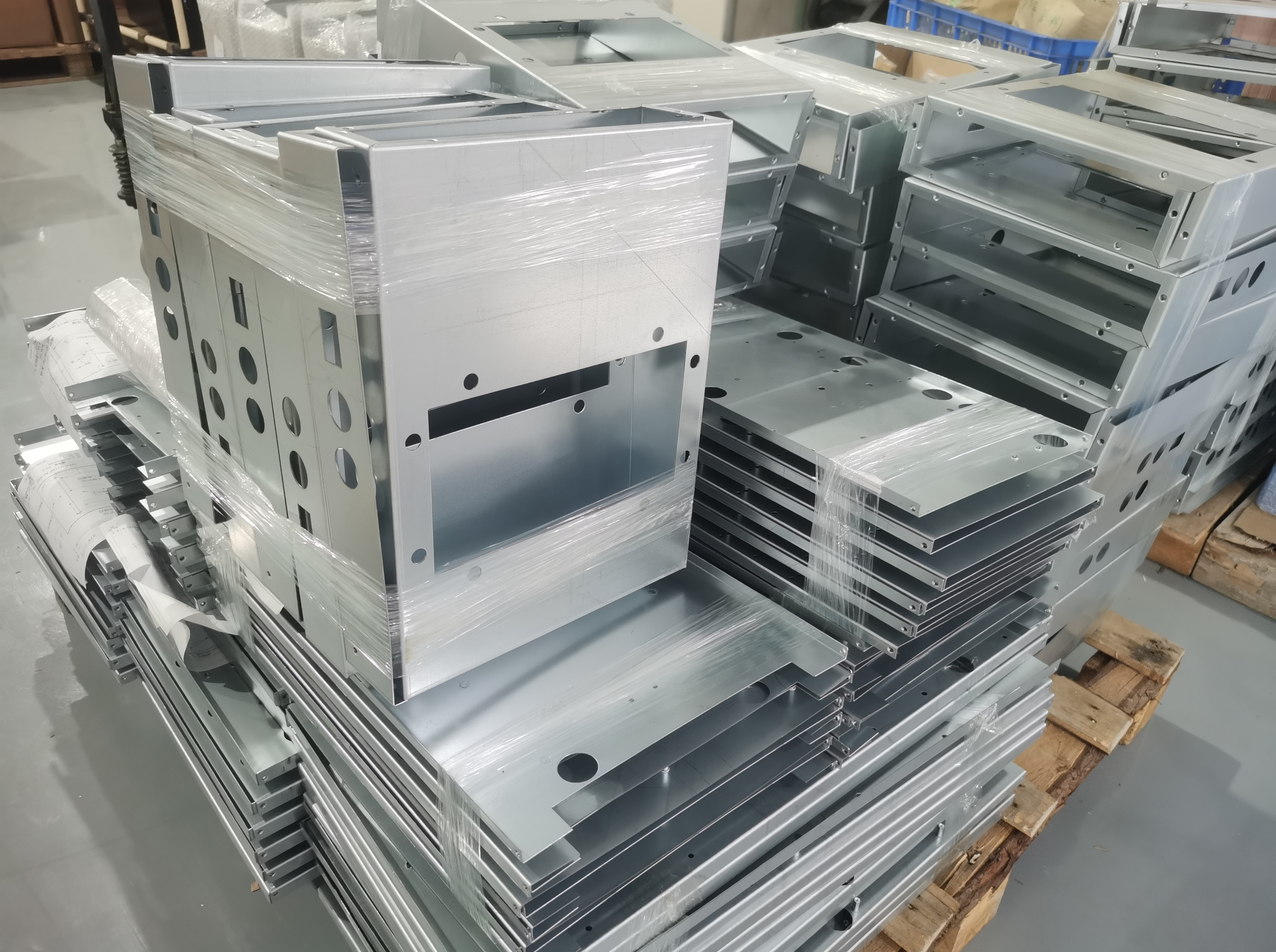

3. Structural Components and Transformer Manufacturing

• Key Processes: Chassis machining, transformer winding, surface treatment (e.g., powder coating)

• Core Outputs: Welding machine housing, heat sink, wound transformer

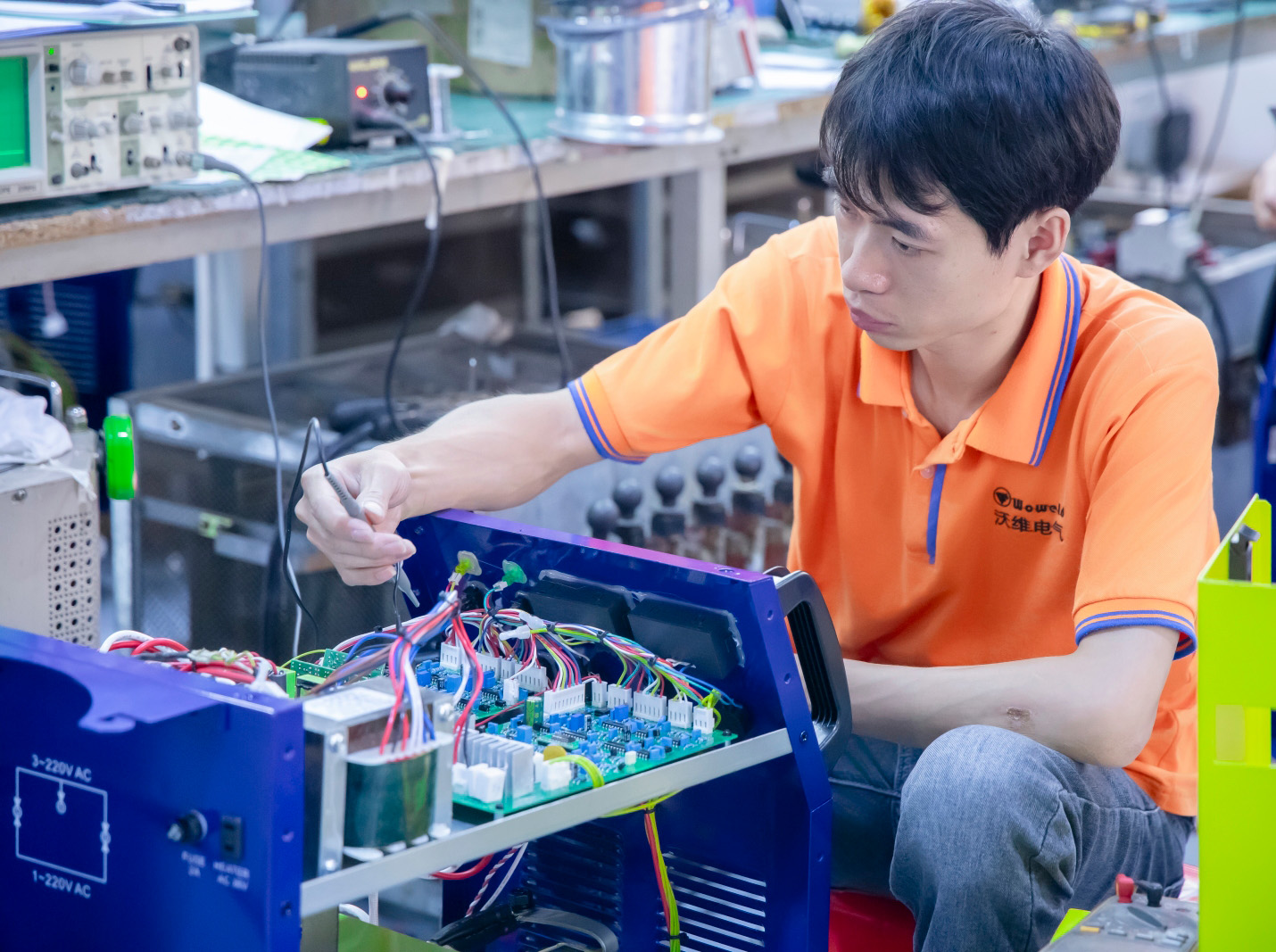

4. Assembly and Testing

• Key Processes: Complete machine assembly, online debugging, aging test, final inspection

• Core Outputs: Performance-qualified, ready-to-package finished welding machine

National service hotline:+86 755 8690 9021

National service hotline:+86 755 8690 9021

.png)

.jpg)